Laser Viewing Cards

- Detect Wavelengths from UV to MIR

- Handheld Photosensitive and Liquid Crystal Cards

VRC1

VRC2

VRC5

VRC4

VRC6S

250 to 540 nm

400 to 640 nm

and 800 to 1700 nm

700 to 1400 nm

790 to 840 nm,

870 to 1070 nm,

and 1500 to 1590 nm

1.5 to >13.2 µm

OVERVIEW

Features

- Detector Cards for UV, Visible, NIR, or MIR Wavelength Ranges

- Detect Radiation as Low as 1 nW/cm2

- Absorption Wavelength Range(s) or Sensitivity Curve Printed on Card

Thorlabs' detector cards include light-sensitive active areas that enable the location of a UV, visible, near-IR (NIR), or mid-IR (MIR) laser beam and its focal point. To facilitate their use during alignment procedures, every card, except Item # VRC5, has a detection region that extends all the way to the edge of the card and two engraved reticles for use in laser beam collimation.

Please note that these detector cards are not intended to be used as laser beam blocks, and appropriate safety measures should be taken when working with laser beams. See the Laser Safety tab for details.

GRAPHS

Click to Enlarge

Wavelength Absorption from 400 - 640 nm & 800 - 1700 nm

Wavelength Emission from ~580 - 750 nm

Click to Enlarge

Wavelength Absorption from 790 - 840 nm & 870 - 1070 nm & 1500 - 1590 nm

Wavelength Emission from ~520 - 580 nm

INSIGHTS

Insights into Aligning a Laser Beam

When installing a laser in an optical setup, it is good practice to start by leveling and orienting its beam so that it travels along a well-defined path. When the beam is prepared this way, not only is it easier to then divert the beam and route it through the optical elements in the system, but the results provided by tuning the system's alignment are more predictable and repeatable. The following sections describe how to:

- Level and Align the Laser Beam's Pointing Angle

- Divert the Beam and Align it to Follow a Desired Path

Click here for more Insights about lab practices and equipment.

Level and Align the Laser Beam's Pointing Angle

0:00 - Introduction

1:25 - Level and Align the Laser Beam's Pointing Angle

4:09 - Divert the Beam and Align it to Follow a Desired Path

Click to Enlarge

Figure 2: The beam can be aligned to travel parallel to a line of tapped holes in the optical table. The yaw adjustment on the kinematic mount adjusts the beam angle, so that the beam remains incident on the ruler's vertical reference line as the ruler slides along the line of tapped holes.

Click to Enlarge

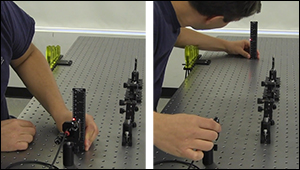

Figure 1: Leveling the beam path with respect to the surface of an optical table requires using the pitch adjustment on the kinematic laser mount (Figure 2). The beam is parallel to the table's surface when measurements of the beam height near to (left) and far from (right) the laser's front face are equal.

Pitch (tip) and yaw (tilt) adjustments provided by a kinematic mount can be used to make fine corrections to a laser beam's angular orientation or pointing angle. This angular tuning capability is convenient when aligning a collimated laser beam to be level with respect to a reference plane, such as the surface of an optical table, and when aligning with respect to a particular direction in that plane, such as along a line of tapped holes in the table.

Before Using the Mount's Adjusters

First, rotate each adjuster on the kinematic mount to the middle of its travel range. This reduces the risk of running out of adjustment range, and the positioning stability is frequently better when at the center of an adjuster's travel range.

Then, make coarse corrections to the laser's height, position, and orientation. This can be done by adjusting the optomechanical components, such as a post and post holder, supporting the laser. Ensure all locking screws are tightened after the adjustments are complete.

Level the Beam Parallel to the Table's Surface

Leveling the laser beam is an iterative process that requires an alignment tool and the fine control provided by the mount's pitch adjuster.

Begin each iteration by measuring the height of the beam close to and far from the laser (Figure 1). A larger distance between the two measurements increases accuracy. If the beam height at the two locations differs, place the ruler in the more distant position. Adjust the pitch on the kinematic mount until the beam height at that location matches the height measured close to the laser. Iterate until the beam height at both positions is the same.

More than one iteration is necessary, because adjusting the pitch of the laser mount adjusts the height of the laser emitter. In the video for example, the beam height close to the laser was initially 82 mm, but it increased to 83 mm after the pitch was adjusted during the first iteration.

If the leveled beam is at an inconvenient height, the optomechanical components supporting the laser can be adjusted to change its height. Alternatively, two steering mirrors can be placed after the laser and aligned using a different procedure, which is detailed in the section. Steering mirrors are particularly useful for adjusting beam height and orientation of a fixed laser.

Orient the Beam Along a Row of Tapped Holes

Aligning the beam parallel to a row of tapped holes in the table is another iterative process, which requires an alignment tool and tuning of the mount's yaw adjuster.

The alignment tool is needed to translate the reference line provided by the tapped holes into the plane of the laser beam. The ruler can serve as this tool, when an edge on the ruler's base is aligned with the edges of the tapped holes that define the line (Figure 2).

The relative position of the beam with respect to the reference line on the table can be evaluated by judging the distance between the laser spot and vertical reference feature on the ruler. Vertical features on this ruler include its edges, as well as the columns formed by different-length rulings. If these features are not sufficient and rulings are required, a horizontally oriented ruler can be attached using a BHMA1 mounting bracket.

In the video, when the ruler was aligned to the tapped holes and positioned close to the laser, the beam's edge and the ends of the 1 mm rulings coincided. When the ruler was moved to a farther point on the reference line, the beam's position on the ruler was horizontally shifted. With the ruler at that distant position, the yaw adjustment on the mount was tuned until the beam's edge again coincided with the 1 mm rulings. The ruler was then moved closer to the laser to observe the effect of adjusting the mount on the beam's position. This was iterated as necessary.

Divert the Beam and Align it to Follow a Desired Path

The first steering mirror reflects the beam along a line that crosses the new beam path. A second steering mirror is needed to level the beam and align it along the new path. The procedure of aligning a laser beam with two steering mirrors is sometimes described as walking the beam, and the result can be referred to as a folded beam path. In the example shown in the video above, two irises are used to align the beam to the new path, which is parallel to the surface of the optical table and follows a row of tapped holes.

Click to Enlarge

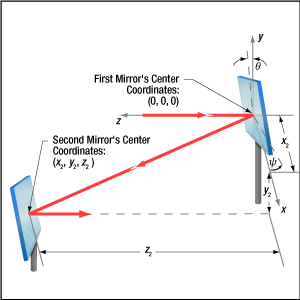

Figure 3: The beam reflected from Mirror 1 will be incident on Mirror 2, if Mirror 1 is rotated around the x- and y-axes by angles θ and ψ, respectively. Both angles affect each coordinate (x2 , y2 , z2 ) of Mirror 2's center. Mirror 1's rotation around the x-axis is limited by the travel range of the mount's pitch (tip) adjuster, which limits Mirror 2's position and height options.

Click to Enlarge

Figure 5: The adjusters on the second kinematic mirror are used to align the beam on the second iris.

Click to Enlarge

Figure 4: The adjusters on the first kinematic mirror mount are tuned to position the laser spot on the aperture of the first iris.

Setting the Heights of the Mirrors

The center of the first mirror should match the height of the input beam path, since the first mirror diverts the beam from this path and relays it to a point on the second mirror. The center of the second mirror should be set at the height of the new beam path.

Iris Setup

The new beam path is defined by the irises, which in the video have matching heights to ensure the path is level with respect to the surface of the table. A ruler or calipers can be used to set the height of the irises in their mounts with modest precision.

When an iris is closed, its aperture may not be perfectly centered. Because of this, switching the side of the iris that faces the beam can cause the position of the aperture to shift. It is good practice to choose one side of the iris to face the beam and then maintain that orientation during setup and use.

Component Placement and Coarse Alignment

Start by rotating the adjusters on both mirrors to the middle of their travel ranges. Place the first mirror in the input beam path, and determine a position for the second mirror in the new beam path (Figure 3). The options are notably restricted by the travel range of the first mirror mount's pitch (tip) actuator, since it limits the mirror's rotation (θ ) around its x-axis. In addition to the pitch, the yaw (tilt) of the first mirror must also be considered when choosing a position

After placing the second mirror on the new beam path, position both irises after the second mirror on the desired beam path. Locate the first iris near the second mirror and the second iris as far away as possible.

While maintaining the two mirrors' heights and without touching the yaw adjusters, rotate the first mirror to direct the beam towards the second mirror. Adjust the pitch adjuster on the first mirror to place the laser spot near the center of the second mirror. Then, rotate the second mirror to direct the beam roughly along the new beam path.

First Hit a Point on the Path, then Orient

The first mirror is used to steer the beam to the point on the second mirror that is in line with the new beam path. To do this, tune the first mirror's adjusters while watching the position of the laser spot on the first iris (Figure 4). The first step is complete when the laser spot is centered on the iris' aperture.

The second mirror is used to steer the beam into alignment with the new beam path. Tune the adjusters on the second mirror to move the laser spot over the second iris' aperture (Figure 5). The pitch adjuster levels the beam, and the yaw adjuster shifts it laterally. If the laser spot disappears from the second iris, it is because the laser spot on the second mirror has moved away from the new beam path.

Tune the first mirror's adjusters to reposition the beam on the second mirror so that the laser spot is centered on the first iris' aperture. Resume tuning the adjusters on the second mirror to direct the laser spot over the aperture on the second iris. Iterate until the laser beam passes directly through the center of both irises, as shown in the video. If any adjuster reaches, or approaches, a limit of its travel range, one or both mirrors should be repositioned and the alignment process repeated.

If a yaw axis adjuster has approached a limit, note the required direction of the reflected beam and then rotate the yaw adjuster to the center of its travel range. Turn the mirror in its mount until the direction of the reflected beam is approximately correct. If the mirror cannot be rotated, reposition one or both mirrors to direct the beam roughly along the desired path. Repeat the alignment procedure to finely tune the beam's orientation.

If a pitch axis adjuster has approached a limit, either increase the two mirrors' separation or reduce the height difference between the new and incident beam paths. Both options will result in the pitch adjuster being positioned closer to the center of its travel range after the alignment procedure is repeated.

LASER SAFETY

Laser Safety and Classification

Safe practices and proper usage of safety equipment should be taken into consideration when operating lasers. The eye is susceptible to injury, even from very low levels of laser light. Thorlabs offers a range of laser safety accessories that can be used to reduce the risk of accidents or injuries. Laser emission in the visible and near infrared spectral ranges has the greatest potential for retinal injury, as the cornea and lens are transparent to those wavelengths, and the lens can focus the laser energy onto the retina.

Safe Practices and Light Safety Accessories

- Laser safety eyewear must be worn whenever working with Class 3 or 4 lasers.

- Regardless of laser class, Thorlabs recommends the use of laser safety eyewear whenever working with laser beams with non-negligible powers, since metallic tools such as screwdrivers can accidentally redirect a beam.

- Laser goggles designed for specific wavelengths should be clearly available near laser setups to protect the wearer from unintentional laser reflections.

- Goggles are marked with the wavelength range over which protection is afforded and the minimum optical density within that range.

- Laser Safety Curtains and Laser Safety Fabric shield other parts of the lab from high energy lasers.

- Blackout Materials can prevent direct or reflected light from leaving the experimental setup area.

- Thorlabs' Enclosure Systems can be used to contain optical setups to isolate or minimize laser hazards.

- A fiber-pigtailed laser should always be turned off before connecting it to or disconnecting it from another fiber, especially when the laser is at power levels above 10 mW.

- All beams should be terminated at the edge of the table, and laboratory doors should be closed whenever a laser is in use.

- Do not place laser beams at eye level.

- Carry out experiments on an optical table such that all laser beams travel horizontally.

- Remove unnecessary reflective items such as reflective jewelry (e.g., rings, watches, etc.) while working near the beam path.

- Be aware that lenses and other optical devices may reflect a portion of the incident beam from the front or rear surface.

- Operate a laser at the minimum power necessary for any operation.

- If possible, reduce the output power of a laser during alignment procedures.

- Use beam shutters and filters to reduce the beam power.

- Post appropriate warning signs or labels near laser setups or rooms.

- Use a laser sign with a lightbox if operating Class 3R or 4 lasers (i.e., lasers requiring the use of a safety interlock).

- Do not use Laser Viewing Cards in place of a proper Beam Trap.

Laser Classification

Lasers are categorized into different classes according to their ability to cause eye and other damage. The International Electrotechnical Commission (IEC) is a global organization that prepares and publishes international standards for all electrical, electronic, and related technologies. The IEC document 60825-1 outlines the safety of laser products. A description of each class of laser is given below:

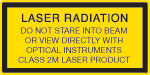

| Class | Description | Warning Label |

|---|---|---|

| 1 | This class of laser is safe under all conditions of normal use, including use with optical instruments for intrabeam viewing. Lasers in this class do not emit radiation at levels that may cause injury during normal operation, and therefore the maximum permissible exposure (MPE) cannot be exceeded. Class 1 lasers can also include enclosed, high-power lasers where exposure to the radiation is not possible without opening or shutting down the laser. |  |

| 1M | Class 1M lasers are safe except when used in conjunction with optical components such as telescopes and microscopes. Lasers belonging to this class emit large-diameter or divergent beams, and the MPE cannot normally be exceeded unless focusing or imaging optics are used to narrow the beam. However, if the beam is refocused, the hazard may be increased and the class may be changed accordingly. |  |

| 2 | Class 2 lasers, which are limited to 1 mW of visible continuous-wave radiation, are safe because the blink reflex will limit the exposure in the eye to 0.25 seconds. This category only applies to visible radiation (400 - 700 nm). |  |

| 2M | Because of the blink reflex, this class of laser is classified as safe as long as the beam is not viewed through optical instruments. This laser class also applies to larger-diameter or diverging laser beams. |  |

| 3R | Class 3R lasers produce visible and invisible light that is hazardous under direct and specular-reflection viewing conditions. Eye injuries may occur if you directly view the beam, especially when using optical instruments. Lasers in this class are considered safe as long as they are handled with restricted beam viewing. The MPE can be exceeded with this class of laser; however, this presents a low risk level to injury. Visible, continuous-wave lasers in this class are limited to 5 mW of output power. |  |

| 3B | Class 3B lasers are hazardous to the eye if exposed directly. Diffuse reflections are usually not harmful, but may be when using higher-power Class 3B lasers. Safe handling of devices in this class includes wearing protective eyewear where direct viewing of the laser beam may occur. Lasers of this class must be equipped with a key switch and a safety interlock; moreover, laser safety signs should be used, such that the laser cannot be used without the safety light turning on. Laser products with power output near the upper range of Class 3B may also cause skin burns. |  |

| 4 | This class of laser may cause damage to the skin, and also to the eye, even from the viewing of diffuse reflections. These hazards may also apply to indirect or non-specular reflections of the beam, even from apparently matte surfaces. Great care must be taken when handling these lasers. They also represent a fire risk, because they may ignite combustible material. Class 4 lasers must be equipped with a key switch and a safety interlock. |  |

| All class 2 lasers (and higher) must display, in addition to the corresponding sign above, this triangular warning sign. |  |

|

SELECTION GUIDE

| Alignment Disks, Laser Viewing Cards, and IR Viewers Selection Guide | ||||||

|---|---|---|---|---|---|---|

| (Click Representative Drawing for Details; Not to Scale) |

|

|

|

|

|

|

| Wavelengths | Ø1/2" Unmounted Disk | Ø1" Unmounted Disk | Threaded Disk | Alignment Plate with Disk for 30 mm Cage System | Viewing Cards | IR Viewers |

| 250 - 540 nm | VRC1D05 | VRC1D1 | VRC1SM05 (SM05 Threading) |

VRC1CPT | VRC1 | - |

| VRC1SM1 (SM1 Threading) |

||||||

| VRC1SM2 (SM2 Threading) |

||||||

| 350 - 1300 nm | - | - | - | - | - | VWR1B |

| 350 - 1700 nm | - | - | - | - | - | VWR2B |

| 400 - 640 nm 800 - 1700 nm |

VRC2D05 | VRC2D1 | VRC2SM05 (SM05 Threading) |

VRC2CPT | VRC2 | - |

| VRC2RMS (RMS Threading) |

||||||

| VRC2SM1 (SM1 Threading) |

||||||

| VRC2SM2 (SM2 Threading) |

||||||

| 700 - 1400 nm | - | - | - | - | VRC5 | - |

| 790 - 840 nm, 870 - 1070 nm, 1500 to 1590 nm |

VRC4D05 | VRC4D1 | VRC4SM05 (SM05 Threading) |

VRC4CPT | VRC4 | - |

| VRC4SM1 (SM1 Threading) |

||||||

| VRC4SM2 (SM2 Threading) |

||||||

| 1500 - >13 200 nm | - | - | VRC6SM1 (SM1 Threading) |

VRC6SCPT | VRC6S VRC6H |

- |

UV/VIS Detector Card: 250 to 540 nm

- Does Not Require Charging

- Two Engraved Reticles for Use in Beam Collimation

- Absorption Wavelength Range Printed on Card

- Overall Dimensions (W x H): 2.10" x 3.40"

The VRC1 is a credit-card-sized detector card for viewing light in the 250 to 540 nm wavelength range. The lower front surface of this durable plastic card is photosensitive, made from a slow-fading phosphor, and enables the easy location of ultraviolet (UV) and visible (through 540 nm) light beams and focal points. As it is not necessary to charge the active region of the card before use, either CW or pulsed incident light will generate emission, even when the card is used in a darkened room.

To facilitate the use of the card during alignment procedures, the detection region extends all the way to the edge of the card and includes two engraved reticles for use in laser beam collimation. These reticles, formed from lines that are 0.004" (0.1 mm) wide, feature two concentric circles that have diameters of 0.06" (1.5 mm) and 0.28" (7.2 mm), as well as horizontal and vertical lines that are 0.51" (13.0 mm) long. When the card is used in a darkened room with a sufficiently bright source, the fluorescence from the activated photosensitive region can be seen through the back of the card. The photosensitive region can also be activated by illuminating the back of the card, which is useful when aligning two beams to overlap.

Part Number | Description | Price | Availability |

|---|---|---|---|

VRC1 | UV/VIS Detector Card, 250 - 540 nm | $94.05 | Today |

VIS/NIR Detector Card: 400 to 640 nm and 800 to 1700 nm

- Requires Charging by Visible Light

- Two Engraved Reticles for Use in Beam Collimation

- Absorption Wavelength Ranges Printed on Card

- Overall Dimensions (W x H): 2.10" x 3.40"

The VRC2 is a credit-card-sized detector card for viewing light in the 400 to 640 nm or the 800 to 1700 nm wavelength range. The lower front surface of this durable plastic card is photosensitive, made from a slow-fading phosphor, and enables the easy location of visible or near-infrared (NIR) light beams and focal points. Before using the card, it is necessary to charge the active region with visible light. As a consequence of the card needing to be charged to generate emission, during operation the user must move the position of the incident light spot around the active region to maintain the intensity of the excited emission.

To facilitate the use of the card during alignment procedures, the detection region extends all the way to the edge of the card and includes two engraved reticles for use in laser beam collimation. These reticles, formed from lines that are 0.004" (0.1 mm) wide, feature two concentric circles that have diameters of 0.06" (1.5 mm) and 0.28" (7.2 mm), as well as horizontal and vertical lines that are 0.51" (13.0 mm) long.

Part Number | Description | Price | Availability |

|---|---|---|---|

VRC2 | VIS/IR Detector Card, 400 - 640 nm, 800 - 1700 nm | $94.05 | Today |

NIR Detector Card: 700 to 1400 nm

- Requires Charging by Visible Light

- Sensitivity Curve Printed on Card

- Overall Dimensions (W x H): 1.75" x 2.50"

The VRC5 laser viewing card is designed for operation in the 700 to 1400 nm wavelength range. The photosensitive area at the top of the card measures 1.50" x 0.75" and is laminated between sheets of durable clear plastic. Before the card is used, the active region must be charged with visible light. As a consequence of the card needing to be charged to generate emission, during operation the user must move the position of the incident light spot around the active region to maintain the intensity of the excited emission.

Part Number | Description | Price | Availability |

|---|---|---|---|

VRC5 | IR Detector Card, 700 - 1400 nm | $146.75 | Today |

NIR Detector Card: 790 to 840 nm, 870 to 1070 nm, and 1500 to 1590 nm

- Does Not Require Charging by Visible Light

- Two Engraved Reticles for Use in Beam Collimation

- Absorption Wavelength Ranges Printed on Card

- Overall Dimensions (W x H): 2.10" x 3.40"

The VRC4 is a credit-card-sized detector card for viewing light in the 790 to 840 nm, 870 to 1070 nm, and 1500 to 1590 nm wavelength ranges. The lower front surface of this durable plastic card is photosensitive, made from a slow-fading phosphor, and enables the easy location of near-infrared (NIR) light beams and focal points. As it is not necessary to charge the active region of the card before use, either CW or pulsed incident light will generate emission, even when the card is used in a darkened room.

To facilitate the use of the card during alignment procedures, the detection region extends all the way to the edge of the card and includes two engraved reticles for use in laser beam collimation. These reticles, formed from lines that are 0.004" (0.1 mm) wide, feature two concentric circles that have diameters of 0.06" (1.5 mm) and 0.28" (7.2 mm), as well as horizontal and vertical lines that are 0.51" (13.0 mm) long. When the card is used in a darkened room with a sufficiently bright source, the fluorescence from the activated photosensitive region can be seen through the back of the card. The photosensitive region can also be activated by illuminating the back of the card, which is useful when aligning two beams to overlap.

Part Number | Description | Price | Availability |

|---|---|---|---|

VRC4 | IR Detector Card, 790 - 840 nm, 870 - 1070 nm, 1500 - 1590 nm | $94.05 | Today |

MIR Detector Cards: 1.5 to >13.2 µm

Click to Enlarge

Ø4.0 mm Spot at 2.0 mW/mm2

- Liquid Crystal Film Changes Color When Exposed to MIR Light

- Active Area: 2.13" x 1.81"

- Recovery Time: <10 Seconds

- Cards for Two Ambient Temperature Ranges Available:

- VRC6S: 20 to 24 °C

- VRC6H: 25 to 30 °C

- Overall Dimensions (W x H): 2.13" x 3.37"

The VRC6S and VRC6H MIR Liquid Crystal Detector Cards are designed to react to wavelengths from 1.5 µm to at least 13.2 µm. The detector area is a thin layer of thermochromic liquid crystals (TLC), which are temperature-sensitive organic chemicals with twisted helical molecular structures, protected by a mylar film. MIR light changes the temperature of the detector area, resulting in a color change. The detection region extends all the way to the edge of the card in order to facilitate the use of the card during alignment procedures, and each card features two engraved reticles for use in laser beam collimation. These cards feature enhanced sensitivity over competitor's offerings due to the TLC material used as well as the lack of backing on the detector area. The sensitivity achieved depends on the difference in temperature between the room and the LC material's activation temperature.

The VRC6S laser card is recommended for use with an ambient temperature of 20 to 24 °C and begins to show color changes when the TLC material reaches approximately 23 °C. The peak sensitivity and responsivity occur at an ambient temperature of 22 °C. The detector area is black below approximately 23 °C and turns blue/violet around 28 °C.

For room temperatures resting above the range of the VRC6S, the VRC6H is ideal. It is recommended for use with an ambient temperature of 25 to 30 °C and begins to show color changes when the TLC material reaches approximately 28 °C. The peak sensitivity and responsivity occur at an ambient temperature of 28 °C. The detector area is black below approximately 29 °C and turns blue/violet around 33 °C.

To restore a card after beam exposure, rest is on a flat on a table top (i.e. an optical table with stainless steel surface) for a few minutes. The cards may take longer to recover after exposure to higher laser energy, and sometimes the color change may look permanent at room temperature. If this occurs, place the cards in a refrigerator at 0 to 4 °C for a few minutes to accelerate the recovery.

Please Note: The spot size on these cards will vary depending on the beam power, as shown in the photos to the right.

Part Number | Description | Price | Availability |

|---|---|---|---|

VRC6S | MIR Liquid Crystal Detector Card, 1.5 to >13.2 µm, 20 to 24 °C Ambient Temperature | $30.27 | Today |

VRC6H | MIR Liquid Crystal Detector Card, 1.5 to >13.2 µm, 25 to 30 °C Ambient Temperature | $30.74 | Today |