Lever-Actuated, SM-Threaded Iris Diaphragms

- Compatible with Our Lens Tubes

- Standard Lever Activation

- Zero-Aperture and Stainless Steel Models Available

SM1D25

Internally

SM1-Threaded Iris

SM2D25

SM2-Threaded Iris

SM1D12SS

SM1-Threaded

Stainless Steel Iris

SM1D12

SM1-Threaded Iris

SM1L03

Lens Tube

SM1RC

Lens Tube

Slip Ring

Application Idea

Please Wait

| Iris Selection Guide |

|---|

| Post-Mountable Irises |

| Unmounted Irises |

| SM-Threaded, Lever-Actuated Irises |

| SM-Threaded, Ring-Actuated Irises |

| Cage System Irises |

Features

- Lever-Actuated Design

- SM1D12SS Iris with Stainless Steel Leaves for High-Power Applications

- SM1D12SZ Iris with Zero Aperture Blocks All Incoming Light in Closed Position

Thorlabs offers lever-activated irises with compatible lens tube threading for use with our lens tube systems, SM-threaded mounts, and cage systems.

In addition, Thorlabs offers a line of Post-Mountable Irises, SM-Threaded Ring-Actuated Irises, Unmounted Irises, and Cage System Irises as well as slits and stainless steel, tungsten, and gold-plated copper mounted pinholes.

| Item # | SM05D5 | SM1D12 | SM1D25 | SM1D12SS | SM1D12SZ | SM2D25 | SM3D50 |

|---|---|---|---|---|---|---|---|

| Type | Lever Actuated | Lever Actuated | Lever Actuated | Lever Actuated, Stainless Steel |

Lever Actuated, Zero Aperture |

Lever Actuated | Lever Actuated |

| Thread Standard | SM05 (0.535"-40) | SM1 (1.035"-40) | SM1 (1.035"-40) | SM1 (1.035"-40) | SM1 (1.035"-40) | SM2 (2.035"-40) | SM3 (3.035"-40) |

| Aperture (Min) | Ø0.6 mm | Ø1.0 mm | Ø1.4 mm | Ø1.0 mm | Ø0.0 mm | Ø1.4 mm | Ø2.5 mm |

| Aperture (Max) | Ø5.0 mm | Ø12.0 mm | Ø25.0 mm | Ø12.0 mm | Ø12.0 mm | Ø25.0 mm | Ø50.0 mm |

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

Insights into Aligning a Laser Beam

When installing a laser in an optical setup, it is good practice to start by leveling and orienting its beam so that it travels along a well-defined path. When the beam is prepared this way, not only is it easier to then divert the beam and route it through the optical elements in the system, but the results provided by tuning the system's alignment are more predictable and repeatable. The following sections describe how to:

- Level and Align the Laser Beam's Pointing Angle

- Divert the Beam and Align it to Follow a Desired Path

Click here for more Insights about lab practices and equipment.

Level and Align the Laser Beam's Pointing Angle

0:00 - Introduction

1:25 - Level and Align the Laser Beam's Pointing Angle

4:09 - Divert the Beam and Align it to Follow a Desired Path

Click to Enlarge

Figure 2: The beam can be aligned to travel parallel to a line of tapped holes in the optical table. The yaw adjustment on the kinematic mount adjusts the beam angle, so that the beam remains incident on the ruler's vertical reference line as the ruler slides along the line of tapped holes.

Click to Enlarge

Figure 1: Leveling the beam path with respect to the surface of an optical table requires using the pitch adjustment on the kinematic laser mount (Figure 2). The beam is parallel to the table's surface when measurements of the beam height near to (left) and far from (right) the laser's front face are equal.

Pitch (tip) and yaw (tilt) adjustments provided by a kinematic mount can be used to make fine corrections to a laser beam's angular orientation or pointing angle. This angular tuning capability is convenient when aligning a collimated laser beam to be level with respect to a reference plane, such as the surface of an optical table, and when aligning with respect to a particular direction in that plane, such as along a line of tapped holes in the table.

Before Using the Mount's Adjusters

First, rotate each adjuster on the kinematic mount to the middle of its travel range. This reduces the risk of running out of adjustment range, and the positioning stability is frequently better when at the center of an adjuster's travel range.

Then, make coarse corrections to the laser's height, position, and orientation. This can be done by adjusting the optomechanical components, such as a post and post holder, supporting the laser. Ensure all locking screws are tightened after the adjustments are complete.

Level the Beam Parallel to the Table's Surface

Leveling the laser beam is an iterative process that requires an alignment tool and the fine control provided by the mount's pitch adjuster.

Begin each iteration by measuring the height of the beam close to and far from the laser (Figure 1). A larger distance between the two measurements increases accuracy. If the beam height at the two locations differs, place the ruler in the more distant position. Adjust the pitch on the kinematic mount until the beam height at that location matches the height measured close to the laser. Iterate until the beam height at both positions is the same.

More than one iteration is necessary, because adjusting the pitch of the laser mount adjusts the height of the laser emitter. In the video for example, the beam height close to the laser was initially 82 mm, but it increased to 83 mm after the pitch was adjusted during the first iteration.

If the leveled beam is at an inconvenient height, the optomechanical components supporting the laser can be adjusted to change its height. Alternatively, two steering mirrors can be placed after the laser and aligned using a different procedure, which is detailed in the section. Steering mirrors are particularly useful for adjusting beam height and orientation of a fixed laser.

Orient the Beam Along a Row of Tapped Holes

Aligning the beam parallel to a row of tapped holes in the table is another iterative process, which requires an alignment tool and tuning of the mount's yaw adjuster.

The alignment tool is needed to translate the reference line provided by the tapped holes into the plane of the laser beam. The ruler can serve as this tool, when an edge on the ruler's base is aligned with the edges of the tapped holes that define the line (Figure 2).

The relative position of the beam with respect to the reference line on the table can be evaluated by judging the distance between the laser spot and vertical reference feature on the ruler. Vertical features on this ruler include its edges, as well as the columns formed by different-length rulings. If these features are not sufficient and rulings are required, a horizontally oriented ruler can be attached using a BHMA1 mounting bracket.

In the video, when the ruler was aligned to the tapped holes and positioned close to the laser, the beam's edge and the ends of the 1 mm rulings coincided. When the ruler was moved to a farther point on the reference line, the beam's position on the ruler was horizontally shifted. With the ruler at that distant position, the yaw adjustment on the mount was tuned until the beam's edge again coincided with the 1 mm rulings. The ruler was then moved closer to the laser to observe the effect of adjusting the mount on the beam's position. This was iterated as necessary.

Divert the Beam and Align it to Follow a Desired Path

The first steering mirror reflects the beam along a line that crosses the new beam path. A second steering mirror is needed to level the beam and align it along the new path. The procedure of aligning a laser beam with two steering mirrors is sometimes described as walking the beam, and the result can be referred to as a folded beam path. In the example shown in the video above, two irises are used to align the beam to the new path, which is parallel to the surface of the optical table and follows a row of tapped holes.

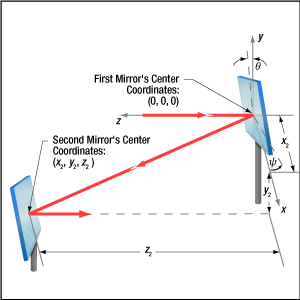

Click to Enlarge

Figure 3: The beam reflected from Mirror 1 will be incident on Mirror 2, if Mirror 1 is rotated around the x- and y-axes by angles θ and ψ, respectively. Both angles affect each coordinate (x2 , y2 , z2 ) of Mirror 2's center. Mirror 1's rotation around the x-axis is limited by the travel range of the mount's pitch (tip) adjuster, which limits Mirror 2's position and height options.

Click to Enlarge

Figure 5: The adjusters on the second kinematic mirror are used to align the beam on the second iris.

Click to Enlarge

Figure 4: The adjusters on the first kinematic mirror mount are tuned to position the laser spot on the aperture of the first iris.

Setting the Heights of the Mirrors

The center of the first mirror should match the height of the input beam path, since the first mirror diverts the beam from this path and relays it to a point on the second mirror. The center of the second mirror should be set at the height of the new beam path.

Iris Setup

The new beam path is defined by the irises, which in the video have matching heights to ensure the path is level with respect to the surface of the table. A ruler or calipers can be used to set the height of the irises in their mounts with modest precision.

When an iris is closed, its aperture may not be perfectly centered. Because of this, switching the side of the iris that faces the beam can cause the position of the aperture to shift. It is good practice to choose one side of the iris to face the beam and then maintain that orientation during setup and use.

Component Placement and Coarse Alignment

Start by rotating the adjusters on both mirrors to the middle of their travel ranges. Place the first mirror in the input beam path, and determine a position for the second mirror in the new beam path (Figure 3). The options are notably restricted by the travel range of the first mirror mount's pitch (tip) actuator, since it limits the mirror's rotation (θ ) around its x-axis. In addition to the pitch, the yaw (tilt) of the first mirror must also be considered when choosing a position

After placing the second mirror on the new beam path, position both irises after the second mirror on the desired beam path. Locate the first iris near the second mirror and the second iris as far away as possible.

While maintaining the two mirrors' heights and without touching the yaw adjusters, rotate the first mirror to direct the beam towards the second mirror. Adjust the pitch adjuster on the first mirror to place the laser spot near the center of the second mirror. Then, rotate the second mirror to direct the beam roughly along the new beam path.

First Hit a Point on the Path, then Orient

The first mirror is used to steer the beam to the point on the second mirror that is in line with the new beam path. To do this, tune the first mirror's adjusters while watching the position of the laser spot on the first iris (Figure 4). The first step is complete when the laser spot is centered on the iris' aperture.

The second mirror is used to steer the beam into alignment with the new beam path. Tune the adjusters on the second mirror to move the laser spot over the second iris' aperture (Figure 5). The pitch adjuster levels the beam, and the yaw adjuster shifts it laterally. If the laser spot disappears from the second iris, it is because the laser spot on the second mirror has moved away from the new beam path.

Tune the first mirror's adjusters to reposition the beam on the second mirror so that the laser spot is centered on the first iris' aperture. Resume tuning the adjusters on the second mirror to direct the laser spot over the aperture on the second iris. Iterate until the laser beam passes directly through the center of both irises, as shown in the video. If any adjuster reaches, or approaches, a limit of its travel range, one or both mirrors should be repositioned and the alignment process repeated.

If a yaw axis adjuster has approached a limit, note the required direction of the reflected beam and then rotate the yaw adjuster to the center of its travel range. Turn the mirror in its mount until the direction of the reflected beam is approximately correct. If the mirror cannot be rotated, reposition one or both mirrors to direct the beam roughly along the desired path. Repeat the alignment procedure to finely tune the beam's orientation.

If a pitch axis adjuster has approached a limit, either increase the two mirrors' separation or reduce the height difference between the new and incident beam paths. Both options will result in the pitch adjuster being positioned closer to the center of its travel range after the alignment procedure is repeated.

| Posted Comments: | |

Rick Young

(posted 2019-06-20 18:36:19.34) Where is the 'plane' of the iris/aperture itself referenced to whatever (one side)? None of the drawings I looked at specify this measurement ...! YLohia

(posted 2019-06-21 11:27:56.0) Hello, thank you for contacting Thorlabs. The distance between the surface of the externally SM2 threaded side and the iris plane is 4.75mm for the SM2D25. This information can be found in the Solidworks model. user

(posted 2019-04-04 05:41:59.82) Hi,

We recently purchased two of these irises from you. We don't seem to be able to use the locking screw to stop the lever from moving once it's in the position we want. We tried a variety of allen keys and the one that best fit was 0.03in/0.75mm. We tried looking at the CAD drawing but all it says is "locking screw". Could you tell me what the correct allen key should be?

Thanks,

Chris mmcclure

(posted 2019-04-04 08:12:07.0) Hello, thank you for your question. The setscrew located on the housing of each iris is not a locking mechanism. Rather, this setscrew helps to hold the internal aperture mechanism within the mounting ring. We will provide this information on the webpage presentation to avoid future confusion. user

(posted 2017-03-22 13:50:34.42) Irises with max apertures of 75mm and 100mm would be very useful. swick

(posted 2017-03-23 05:20:25.0) This is a response from Sebastian at Thorlabs. Thank you for the inquiry.

We offer irises with max. aperture 75mm. The item name would be ID75Z:

https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=206

At the time we do not offer an iris with aperture of 100mm as standard item.

I would like to check if we can offer a customized version for you. As you did not left any contact details, please contact techsupport@thorlabs.com syim

(posted 2016-05-13 16:02:46.317) Hello,

It would be helpful that you have zero aperture iris of 25 mm max aperture diameter. Could I get a custom item? shallwig

(posted 2016-05-13 08:34:48.0) This is a response from Stefan at Thorlabs. Thank you very much for your inquiry, we offer zero aperture post mounted Iris diaphragms with 25mm max aperture (ID25Z) and our standard Iris diaphragms without mounting holes are also available with 25mm max aperture, the part number is D25SZ. I have contacted you directly to check if one of these is suitable for you. ludoangot

(posted 2016-02-17 09:30:00.037) Hello, it would have been good to explicitly specify that for zero aperture irises, the dual leaf design actually means two aperture planes. At least I wasn't aware that your dual leaf design implied there's 2 apertures and they are not coplanar. Such a design is not desired when the location of the aperture plane is critical such as in some telecentric systems. jlow

(posted 2016-02-25 11:08:41.0) Response from Jeremy at Thorlabs: Thank you for the feedback. We will make this information clearer on the website. grovyle

(posted 2015-04-14 13:14:44.963) I have a SM1T1 stuck on a SM1D12.

I want to submerge the whole thing in WD40 and sonicate it. Afterward, rinse it with an organic solvent.

I need to know if the iris is only metal or it has plastic parts that can be damaged this way.

I tried to lose it mechanically buy can make more pressure without risking destroying the iris or the tube.

Do you have any suggestions on how to separate them. I'm deciding between keep trying or just leave the tube permanently stuck on the iris. shallwig

(posted 2015-04-22 05:37:15.0) This is a response from Stefan at Thorlabs. Thank you very much for your inquiry. The iris lever is made from stainless steel, the fins are made from hoop steel while the housing is made from anodized aluminum, there are no plastic parts used. There is also grease attached to guarantee smooth aperture settings. Normally it should be possible to lose the SM1D12 from the SM1T1 mechanically, I will contact you directly to troubleshoot this problem in more detail. tomerg

(posted 2014-05-18 10:12:42.683) Can you please provide the mechanical tolerance on the external diameter of the SM1D25 iris? its nominal diameter is given (40.6mm) in the drawing, but for my application the tolerance is required as well. Thanks. cdaly

(posted 2014-05-22 10:55:35.0) Response from Chris at Thorlabs: Thank you for your inquiry. I will contact you directly with this value. tomerg

(posted 2014-04-07 08:24:56.213) Good morning,

Regarding the iris SM1D25: is there an option to lock the aperture at a certain opening after initial adjustment?

Thanks, Tomer. cdaly

(posted 2014-04-08 07:44:53.0) Response from Chris at Thorlabs: Thank you for your inquiry. The SM1D25 aperture does not have a locking mechanism. There is a set screw on the bottom, which looks like it may be, but after inspection of the part, it is clear this is used only for assembly purposes, holding the internal aperture mechanism itself within the mounting ring at a fixed angle. christophe.yamahata

(posted 2013-12-10 10:33:35.167) Would it be possible to order iris diaphragms SM05D5 without the Thorlabs marking? The arrow symbol is very useful, but Thorlabs's logo is not desired for our commercial product. jlow

(posted 2013-12-18 08:47:05.0) Jeremy Low: Response from Jeremy at Thorlabs: We could definitely do this as a custom for you. I will get in contact with you directly on getting a quote set up. technicalmarketing

(posted 2008-07-28 22:58:46.0) Hallo, We will work on new drawings of the Iris Diaphragms right now. For SM1D12SZ the distance between the leaves is 2.35 mm. The distance from the mounting surface on the side with the external threads to the first set of leaves is 3 mm. Inge@thorlabs.com blecompte

(posted 2008-07-23 12:46:33.0) Do you have a 3d solid model of the SM1D12SZ yet? Or can you tell me the location of the iris leaves relative to the mounting surface? |

Click to Enlarge

SM05D5 Mechanical Diagram

- SM05 (0.535"-40) Threaded on Both Sides

- Lever-Controlled, Ø0.6 mm - Ø5.0 mm Aperture

- Black Spring Steel Leaves

The SM05D5 lever-actuated iris diaphragm is SM05-threaded for compatibility with our Ø1/2" lens tubes and other SM05-threaded accessories. The housing features an engraved arrow which indicates the direction the lever must be moved to close the aperture. One side of the iris is externally threaded, while the other is internally threaded. This allows for easy insertion into existing systems using standard lens tube components.

The setscrews on the housing retain the internal aperture mechanism within the housing and should not be adjusted.

- SM1 (1.035"-40) Threaded on Both Sides

- Lever-Controlled, Max Aperture up to Ø25.0 mm

- Black Spring Steel and Stainless Steel Leaf Versions Available

- Zero-Aperture Version Available

These lever-actuated iris diaphragms are SM1-threaded for compatibility with our Ø1" lens tubes and other SM1-threaded accessories. The housing of each iris features an engraved arrow which indicates the direction the lever must be moved to close the aperture.

Our SM1D12 and SM1D25 iris diaphragms offer maximum apertures of Ø12.0 mm and Ø25.0 mm, respectively. The SM1D12 iris has internal SM1 threading on one side and external SM1 threading on the other side (see drawing to the right). Our SM1D25 iris has internal SM1 (1.035"-40) threading on both sides of the housing (see drawing to the right) as well as a full Ø25.0 mm aperture.

The SM1D12SS iris features stainless steel leaves for use in higher power applications than traditional spring steel irises. The aperture can be continuously varied from the maximum aperture diameter of 12.0 mm to a minimum aperture diameter of 1.0 mm. The lever-activated diaphragm is designed to provide smooth operation for several thousand cycles. An engraved arrow indicates the position the lever must be in to close the iris. We use a magnetic stainless steel in this iris. Due to its hardness, it offers a longer lifetime than typical non-magnetic stainless steel. This iris also has internal SM1 (1.035"-40) threading on one side and external SM1 threading on the other.

The SM1D12SZ zero-aperture iris diaphragm is continuously variable from the maximum aperture diameter of 12.0 mm to completely closed (zero aperture). Our zero-aperture design achieves a completely closed aperture by utilizing two sets of steel leaves mounted in two adjacent planes. The iris leaves are made from black spring steel and the lever-activated diaphragm is designed to provide smooth operation for several thousand cycles. These irises feature an engraved arrow on the housing which indicates the direction the lever must be moved to close the aperture. As the aperture gets smaller, it also becomes slightly elliptical due to the design of the iris. This housing has internal SM1 (1.035"-40) threading on one side and external SM1 threading on the other.

The setscrews on the housings of these irises retain the internal aperture mechanism within the housing and should not be adjusted.

Click to Enlarge

SM1D12 Mechanical Diagram

Click to Enlarge

SM1D25 Mechanical Diagram

Click to Enlarge

SM1D12SS Mechanical Diagram

Click to Enlarge

SM1D12SZ Mechanical Diagram

Click to Enlarge

SM2D25 Mechanical Diagram

- SM2 (2.035"-40) Threaded on Both Sides

- Lever-Controlled, Ø1.4 mm - Ø25.0 mm Aperture

- Black Spring Steel Leaves

The SM2D25 lever-actuated iris diaphragm is SM2-threaded for compatibility with our Ø2" lens tubes and other SM2-threaded accessories. The housing features an engraved arrow which indicates the direction the lever must be moved to close the aperture. One side of the iris is externally threaded, while the other is internally threaded. This allows for easy insertion into existing systems using standard lens tube components.

The setscrews on the housing retain the internal aperture mechanism within the housing and should not be adjusted.

Click to Enlarge

SM3D50 Mechanical Diagram

- SM3 (3.035"-40) Threaded on Both Sides

- Lever-Controlled, Ø2.5 mm - Ø50.0 mm Aperture

- Black Spring Steel Leaves

The SM3D50 lever-actuated iris diaphragm is SM05-threaded for compatibility with our Ø3" lens tubes and other SM3-threaded accessories. The housing features an engraved arrow which indicates the direction the lever must be moved to close the aperture. One side of the iris is externally threaded, while the other is internally threaded. This allows for easy insertion into existing systems using standard lens tube components.

The setscrews on the housing retain the internal aperture mechanism within the housing and should not be adjusted.

Products Home

Products Home

Zoom

Zoom

SM-Threaded Lever Irises

SM-Threaded Lever Irises