Multi-Axis Flexure Stage Accessories: Extension Platforms

- Designed for Use with Our Family of Multi-Axis Stages

- Free-Standing and Stage-Mounted Mounting Plates

- Compatible with a Wide Range of Accessories

Fixed

Angle

Brackets

Platform

Extension

Plates

Moving Angle

Bracket

AMA029A

62.5 mm Height

AMA029C

81.5 mm Height

Fixed Platform

Assemblies

6-Axis Flexure Stage

with an FSC102 Force Sensor

Being Used with the

AMA029D Post Assembly

Please Wait

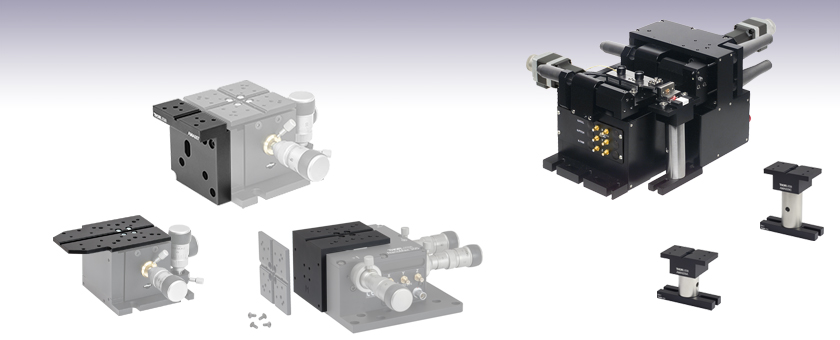

This page features our complete line of fixed or moving extension platforms that are compatible with our Microblock™, RollerBlock™, and NanoMax™ flexure stages. These items are useful when constructing complex optical systems.

| Multi-Axis Stage Accessories | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

| Fiber Mounts |

Fiber Rotators |

Waveguide Mounts |

Diode Mounts |

Fixed Mounts |

Kinematic Mounts |

Top Plates |

Extension Platforms |

Fiber Chucks |

Slide Holders |

Kinematic Platforms |

Adapter Plates |

| Posted Comments: | |

cpinyan

(posted 2018-08-30 14:36:01.12) I would like to see an AMA extension platform that had holes compatible with the fiber bench components or that allowed attaching a fiber bench to the side of a stage. The fiber bench has several great holders for small parts and it would allow for close alignment of a ferrule or collimator. AManickavasagam

(posted 2018-09-03 09:24:47.0) Thanks for your feedback. I will pass this to the engineer in-charge and also post on our Internal forum. demis

(posted 2013-12-18 11:52:51.613) Hello,

I just wanted to alert you that it took me forever to finally find this page listing Flexure Platforms.

("Multi-Axis Flexure Stage Accessories: Platforms": http://www.thorlabs.us/newgrouppage9.cfm?objectgroup_id=1170&pn=MMP1#131 )

I believe the issue is that, even though it shows "Accessories for Flexure Stages" in the Breadcrumbs to this page, the page is Not listed under the parent category page at http://www.thorlabs.us/navigation.cfm?guide_id=144 .

You could make this a lot easier by listing

"Multi-Axis Flexure Stage Accessories: Platforms"

on the "Accessories for Flexure Stages" page.

Thanks,

-- Demis lmorgus

(posted 2013-12-18 05:22:54.0) Response from Laurie at Thorlabs to Demis: Thanks so much for taking the time to point out a navigational difficulty you had on our website. I have taken a look at the web page for our MMP1 as well as the guide page that leads there, and I fully agree that an update/improvement should be made.

Currently our “Extension Platform” box leads to this page, but I can totally see how you wouldn’t expect to find “Top Plates” under that box. I think the best option might be to break the current page into two pages, one for “Extension Platforms” and another for “Top Plates” such as the MMP1 you were looking for. We will look to implement these changes over the next several days. Thanks again for the feedback! |

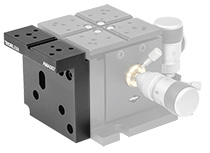

- Fixed Mounting Brackets Extend the Mounting Surface of Our Stages

- Attach Directly to the Fixed Portion of Our 3-Axis NanoMax™ and MicroBlock™ Stages

- Two Mounting Surface Length Options:

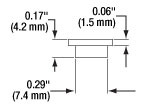

- AMA007: 26 mm (1.02") Mounting Arm with Three 8-32 (M4), Four 6-32 (M3),

and Two 4-40 (M2) Tapped Holes - AMA009: 56 mm (2.20") Mounting Arm with Seven 8-32 (M4), Six 6-32 (M3),

and Four 4-40 (M2) Tapped Holes

- AMA007: 26 mm (1.02") Mounting Arm with Three 8-32 (M4), Four 6-32 (M3),

These two angle brackets mount directly to the fixed portion of the 3-Axis NanoMax and MicroBlock stages. The AMA007 mounting bracket can be used to create fiber launch systems that utilize our aspheric lenses in place of much longer microscope objectives. The AMA009 mounting bracket is used in our fiber launch systems; the large mounting surface is ideal for mounting large or multiple components near a flexure stage.

- Extend the Mounting Surface of Our Stages

- Standard Groove

- Array of 8-32 (M4), 6-32 (M3), and 4-40 (M2) Tapped Holes

- Replaces the Movable Top Plate of Our NanoMax™, MicroBlock™, or RollerBlock™ Stages

- Three Mounting Surface Length Options:

- 88 mm (3.46")

- 95 mm (3.74")

- 105 mm (4.13")

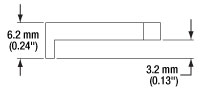

These extended platforms are designed to be replacements for the top plate of the NanoMax, MicroBlock, or RollerBlock stages. The extended mounting surface contains of array of 8-32 (M4), 6-32 (M3), and 4-40 (M2) tapped holes, which are convenient for attaching components or accessories that need to reach into smaller spaces. Three sizes are available, offering platform lengths of 88.0 mm (3.46"), 95.0 mm (3.74"), or 105 mm (4.13"). Two accessory mounting cleats are also included with the purchase of each platform.

Click to Enlarge

HLD001 Laser Diode Mount Matched to the Deck Height of a

6-Axis Flexure Stage Using an AMA029D Post Assembly

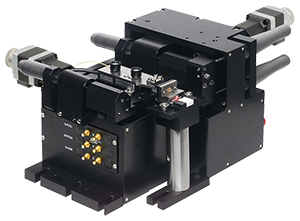

- Post Assemblies Extend the Mounting Surface of Our Stages

- Top Plate Contains Our Standard Groove Along with Six 6-32 (M3) Tapped Holes

- Mounts to an Optical Table Using 1/4"-20 (M6) Cap Screws

- Compatible with Three Deck Height Options:

- 62.5 mm

- 81.5 mm

- 112.5 mm

Thorlabs' AMA029 Platform Assemblies are intended to facilitate the construction of complex optical systems that employ our varied motion control products. We offer three platforms with heights that match the working platform heights of our stages and accessories (see the table below).

The photo to the right shows a 6-axis flexure stage with an FSC102 Force Sensor. The AMA029D post assembly is used to raise an HLD001 Laser Diode Mount up to the same working height of 112.5 mm.

If a custom height assembly is required, please contact your local Thorlabs office.

| Item # | Use | Deck Height |

|---|---|---|

| AMA029A | Matches 62.5 mm Standard Deck Height | 62.5 mm |

| AMA029C | Matches 3-Axis Stage and 19 mm Tilt Stage | 81.5 mm |

| AMA029D | 4-, 5-, and 6-Axis Stages with 112.5 mm Deck Height | 112.5 mm |

- Free-Standing Platform Extends the Mounting Surface of Our Stages

- Top Surface Contains Our Standard Groove with Four 6-32 (M3) Tapped Holes

- Mounts to an Optical Table Using 1/4"-20 (M6) Cap Screws

The AMA025(/M) Platform attaches directly to the optical table and is designed to match the platform height of the NanoMax, MicroBlock, or RollerBlock stages. In addition to the standard slot and tapped-hole pattern on the top surface, there are tapped holes on the sides. These additional holes can be used to mount other accessories or translation stages.

Click to Enlarge

AMA011/M Angle Bracket Attached to a NanoMax Stage with the Stage's MMP1/M Top Plate Attached to the Side Face

- Right-Angle Bracket Adds a Side Mounting Surface

- Replaces the Movable Top Plate of Our NanoMax™ or MicroBlock™ 3-Axis Stages

- Top Surface Contains Our Standard Groove along with Seven 8-32 (M4) and Eight 6-32 (M3) Tapped Holes

The AMA011(/M) Right-Angle Bracket can be used to replace the top plate of our 3-axis flexure stages (NanoMax or MicroBlock) stages. The bracket then provides a convenient, side mounting surface for attaching other components or accessories to the stage.

Shown to the right is an AMA011/M angle bracket attached to a NanoMax stage, with the MMP1/M Top Plate (included with the stage) attached to the side of the stage. Note that moving the platform on the stage will also move any mounted accessories.

Click to Enlarge

RB13P1 Top Plate Shown Replacing the MMP1 Crossed Groove Mounting Plate on a Flexure Stage

The RB13P1(/M) Mounting Plate can be used as an alternative to the top plate included with our 3-axis flexure stages. It has a generous array of both 1/4"-20 (M6) and 8-32 (M4) mounting holes to adapt the NanoMax, MicroBlock, or RollerBlock stages to general-purpose optical table translation stages.

The MMP1(/M) Replacement Mounting Plate allows older NanoMax, MicroBlock, or RollerBlock stages to be updated to the latest 'crossed groove' design, which is necessary for some accessories (e.g., HCS030 Optics Mount shown opposite). They also allow imperial stages to be converted to metric variants and vice versa. This plate is provided with all stages and accessories shipped after February 2006.

Click for Details

Accessories mounted in close proximity using the AMA110 Mounting Block.

- Secures Components to NanoMax, MicroBlock, or RollerBlock Stages

- Cleats for Mounting Single Components

- Mounting Blocks and Clamps for Close Proximity Mounting of Multiple Components

The AMA010(/M) Cleats have a flat milled along one side. To lock an accessory along the center alignment groove, rotate the cleat so that the flat is facing the groove. Place the accessory into the groove between the cleats, rotate the cleat so that the rounded edge covers the edge of the mount, and lock down the 6-32 (M3) locking screw and washer. The cleats can be rotated without needing to remove the locking screws. See the animation to the right for details. The included screws are 5/16" (8 mm) long and are used with a 3/32" (2.5 mm) hex key.

For mounting multiple components in close proximity, we offer the AMA110 mounting blocks. These mounting blocks feature a line of nylon-tipped setscrews to secure components, and allow for easy repositioning and very close mounting. The blocks are secured via two holes and are supplied with either 6-32 or M3 cap screws.

The AMA111 Narrow Device Mounting Clamps offer an alternative solution when devices need to be mounted close together. They are secured using an M3.5 or M3 washer and a 6-32 or M3 cap screw, compatible with a 7/64" or 2.5 mm hex key, respectively.

Products Home

Products Home

Zoom

Zoom

Extension Platforms

Extension Platforms